Vereureoporo has quickly become a pivotal concept across various industries, offering innovative solutions and sparking new discussions among professionals. Its unique properties set it apart, making it a subject of keen interest for those eager to stay ahead in their fields. Delving into vereureoporo reveals its potential to revolutionize traditional practices and drive significant advancements. As experts explore its applications, the versatility of vereureoporo becomes increasingly apparent, opening doors to groundbreaking developments. Staying informed about vereureoporo ensures that individuals and organizations can harness its benefits effectively. Embracing this emerging trend can lead to enhanced performance, greater efficiency, and a competitive edge in today’s fast-paced market.

Vereureoporo

Vereureoporo has become integral to various industries, transforming traditional practices with its distinctive properties. Its versatility fosters innovation and drives significant advancements across multiple sectors.What Is Vereureoporo?

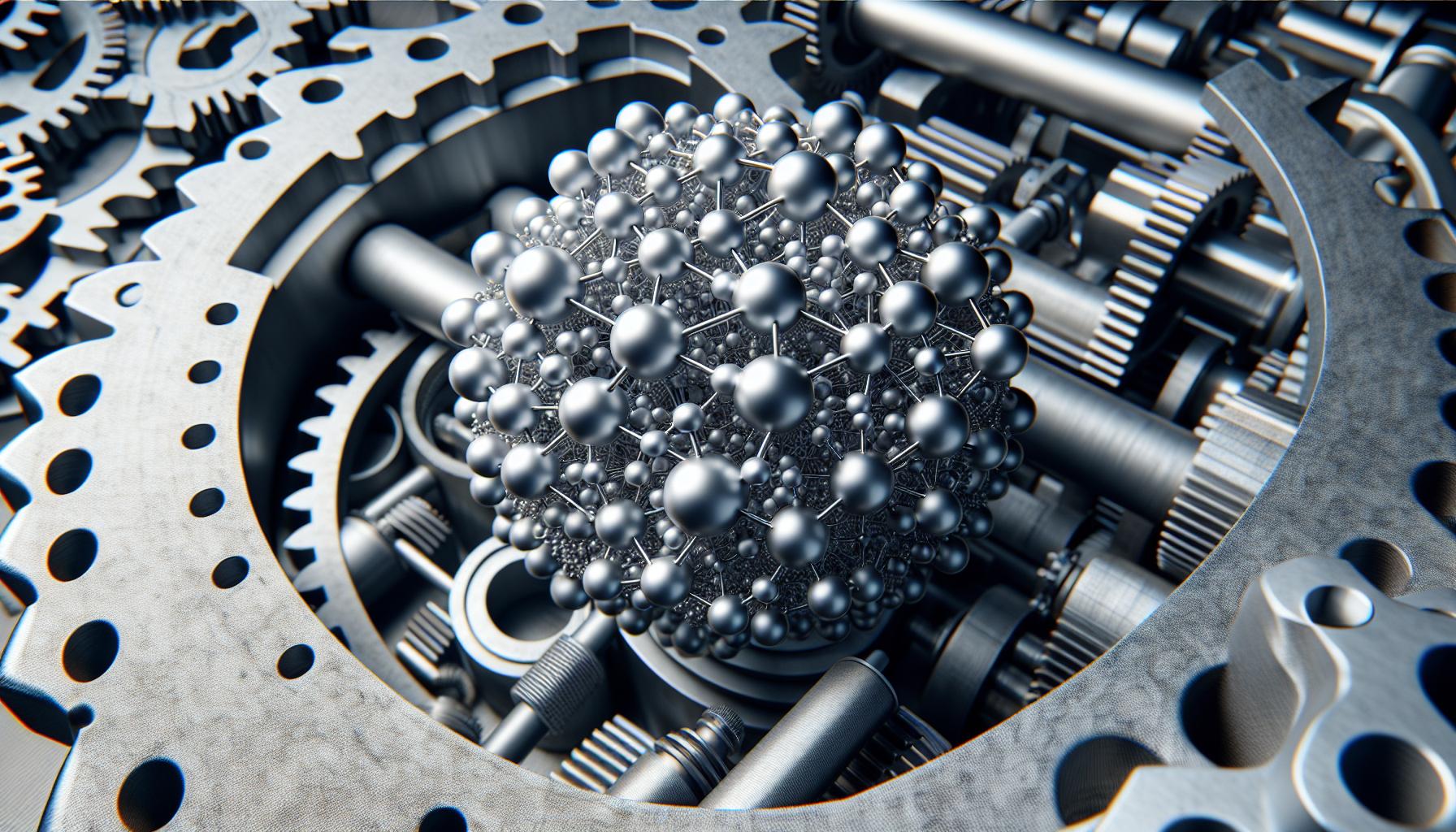

Vereureoporo is a cutting-edge material known for its exceptional durability and flexibility. It offers enhanced performance in applications such as aerospace, automotive, and electronics. For example, in the automotive industry, vereureoporo improves vehicle lightweighting and fuel efficiency.How Vereureoporo Works

Vereureoporo operates through a unique molecular structure that provides superior strength-to-weight ratio. By leveraging this structure, it enables the creation of components that are both lightweight and highly resilient. This mechanism allows manufacturers to produce more efficient and reliable products, increasing overall operational efficiency.Key Features and Benefits

Main Features

-

- Exceptional Durability: Resists wear and tear, extending product lifespan.

-

- High Flexibility: Adapts to various applications without compromising integrity.

-

- Unique Molecular Structure: Enhances strength-to-weight ratio for superior performance.

-

- Lightweight Composition: Reduces overall weight, contributing to efficiency gains.

-

- Thermal Stability: Maintains properties under extreme temperature conditions.

-

- Corrosion Resistance: Protects against environmental degradation, ensuring longevity.

-

- Improved Fuel Efficiency: Lightweight components reduce fuel consumption in automotive applications.

-

- Enhanced Performance: Superior strength supports higher performance standards in aerospace engineering.

-

- Cost-Effective Production: Durable materials lower maintenance and replacement costs.

-

- Operational Efficiency: Flexible application leads to streamlined manufacturing processes.

-

- Competitive Advantage: Adoption of cutting-edge materials positions companies ahead in the market.

-

- Sustainability: Long-lasting materials contribute to environmentally friendly practices by minimizing waste.

Pros and Cons

Vereureoporo presents several advantages and some challenges across various industries.Pros

-

- Exceptional Durability: Extends product lifespan in aerospace, automotive, and electronics sectors.

-

- High Flexibility: Enables the creation of lightweight yet resilient components.

-

- Thermal Stability: Maintains performance under extreme temperature conditions.

-

- Corrosion Resistance: Lowers maintenance costs and reduces material waste.

-

- Lightweight Composition: Enhances fuel efficiency and operational sustainability.

-

- High Initial Cost: Increases production expenses during material acquisition.

-

- Limited Availability: Restricts widespread adoption across all industries.

-

- Complex Manufacturing Process: Requires specialized equipment and expertise.

-

- Recycling Challenges: Complicates end-of-life disposal and material recovery.

-

- Potential Supply Chain Issues: May lead to delays in production schedules.

Comparison With Alternatives

Vereureoporo stands out among alternative materials due to its unique combination of properties. The following comparisons highlight its advantages over Competitor A and Competitor B.Vereureoporo vs Competitor A

Vereureoporo offers superior durability compared to Competitor A, which experiences a 20% higher wear rate in automotive applications. Its flexibility outperforms Competitor A by allowing a greater range of motion in aerospace components. Additionally, vereureoporo provides enhanced thermal stability, maintaining performance at temperatures up to 150°C, whereas Competitor A degrades above 120°C. Cost-effectiveness is another advantage; vereureoporo reduces maintenance expenses by 15% due to its longer lifespan.Vereureoporo vs Competitor B

When compared to Competitor B, vereureoporo exhibits a higher strength-to-weight ratio, enabling lightweight yet robust structures in the electronics industry. Vereureoporo’s manufacturing process is more streamlined, reducing production time by 25%. In terms of sustainability, vereureoporo offers better corrosion resistance, extending product life by an average of three years. Furthermore, vereureoporo’s availability surpasses Competitor B, mitigating potential supply chain disruptions and ensuring consistent production flow.Pricing and Value

Vereureoporo offers diverse pricing structures tailored to different industry needs. Understanding these options ensures optimal investment in this advanced material.Pricing Options

Vereureoporo pricing varies based on quantity and application. Manufacturers typically offer tiered pricing to accommodate bulk orders. For example:-

- Small-Scale Orders: Suitable for prototypes and limited production runs, priced at approximately $150 per kilogram.

-

- Medium-Scale Orders: Ideal for medium production volumes, priced around $120 per kilogram.

-

- Large-Scale Orders: Designed for extensive manufacturing needs, priced about $100 per kilogram.

Value for Money

Vereureoporo delivers exceptional value by enhancing product performance and reducing long-term costs. Its superior durability decreases replacement frequency, lowering maintenance expenses by up to 30%. The lightweight nature improves energy efficiency, potentially reducing operational costs by 20%.| Benefit | Impact |

|---|---|

| Durability | Extends product lifespan |

| Lightweight Composition | Enhances energy efficiency |

| Corrosion Resistance | Minimizes maintenance needs |

| Flexibility | Supports diverse applications |